Our products are manufactured by modern computerized machinery and equipment.a specialized supplier of a fPTO Shaft A PTO Adapter will be useful when operating Victory’s EMSD and EMHD Embankment Flail mowers. The absence of a PTO Adapter could cause the PTO shaft to conflict with the arm weldment, which connects to the CAT I/II 3 point hitch.ull range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage”EPG” brand rotocultivator ploughshares in T.S. total lines produced in our factory have been tested and appraised by the Ministry of Agriculture and have obtained the license of popularizing farm machinery promulgated by the Ministry of Agriculture of the People’s Republic of China. Factory, farms, Construction works , Energy & Mining, agricultural machiner

- Product name:

-

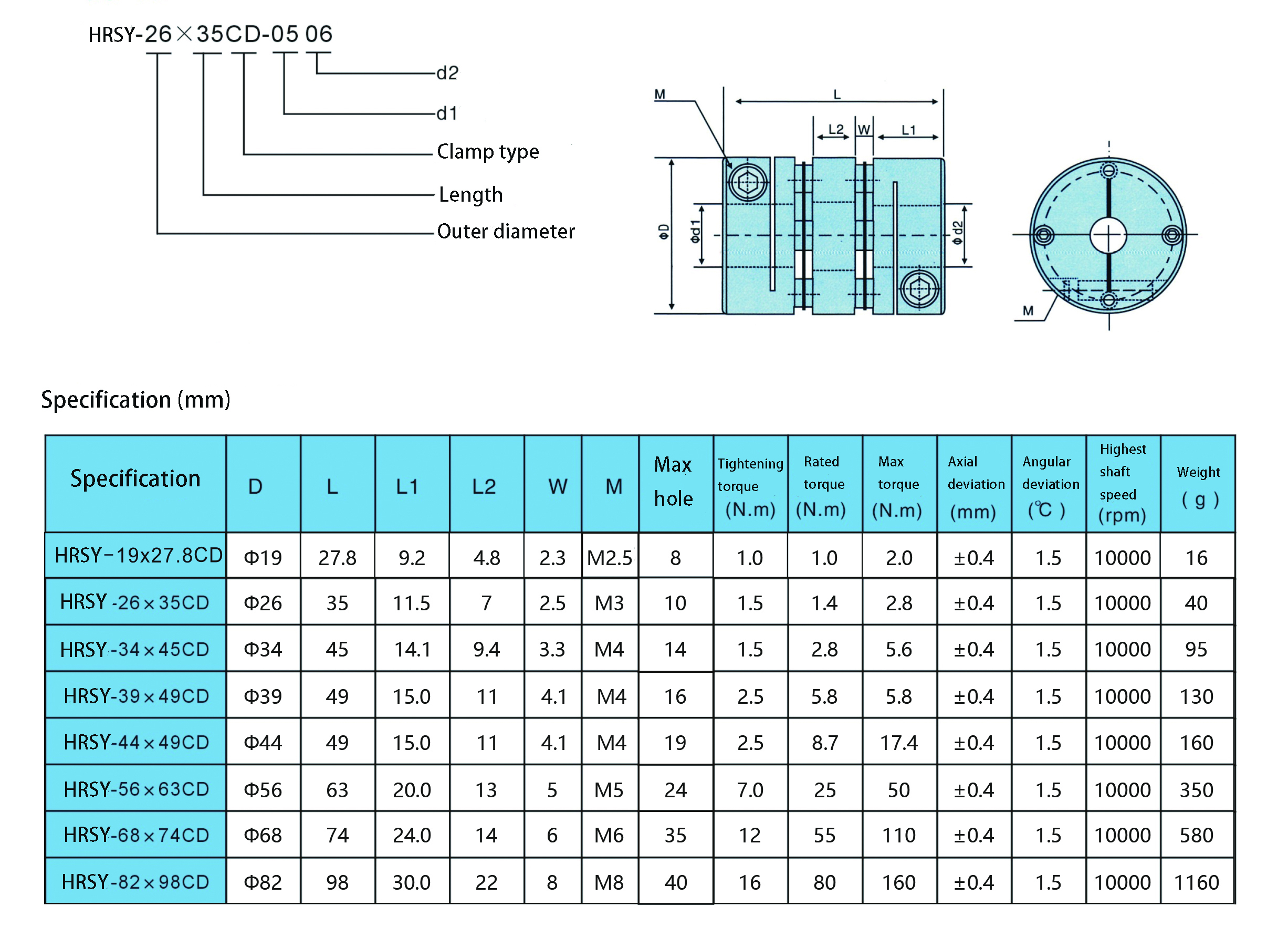

32×41 Aluminum Alloy Double Diaphragm Clamp Coupling

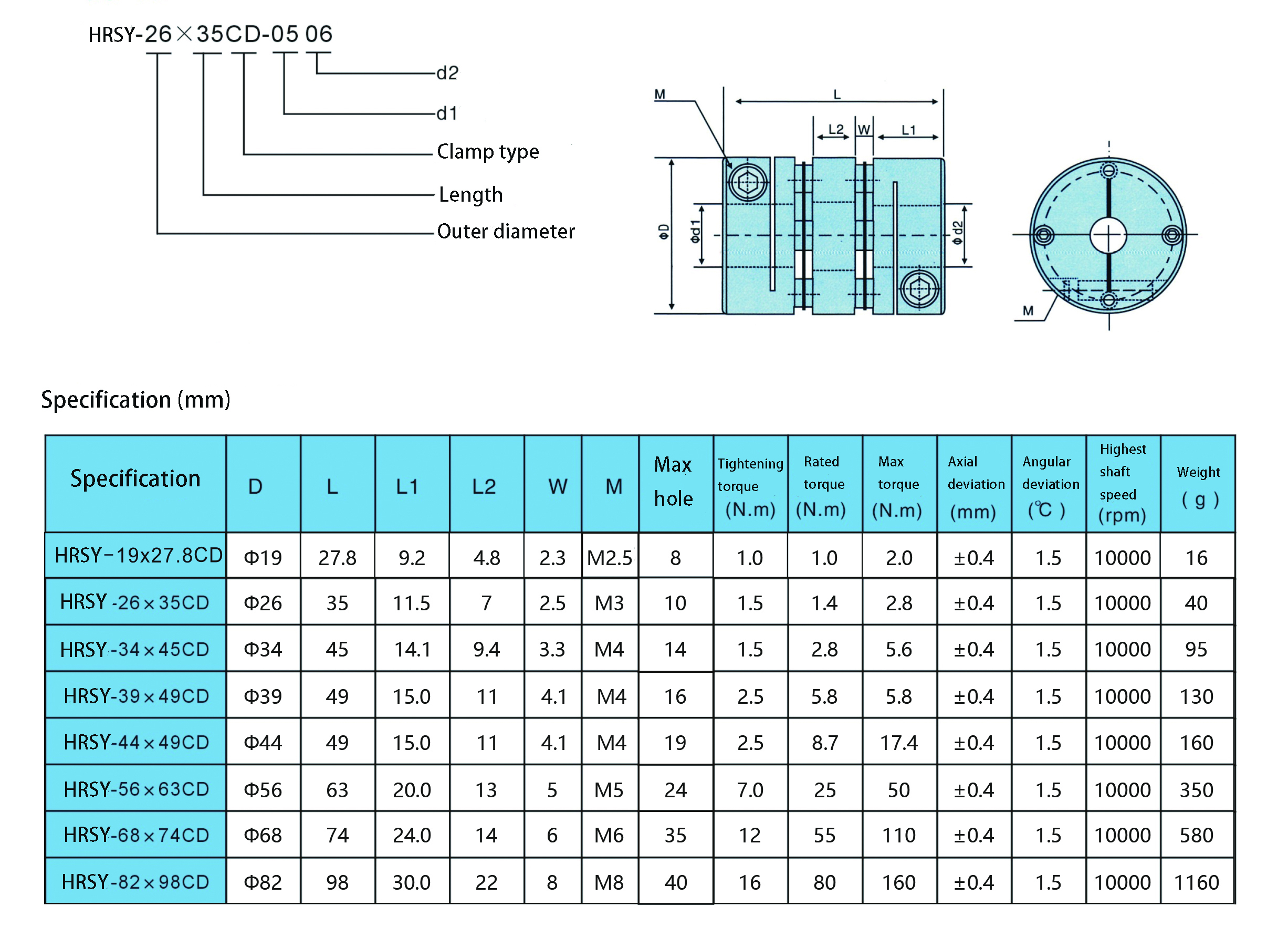

- Size:

-

32×41

-

A rough shaft surface accelerates seal wear. But a finished surface that is too smooth will not support hydrodynamic lubrication of the seal lip. Most oil-seal manufacturers recommend shaft surface roughness between 10 and 20-m in. Ra.

- Surface treatment:

-

Anodizing

- Color:

-

Silver

- Length:

-

20.8-98mm

- Screw:

-

M4

- Max inner hole:

-

14

- Max torque:

-

5.6 N.m

- Weight:

-

0.095kg

- Type:

-

Double Diaphragm Clamp Coupling

Packaging & Delivery

-

Lead Time

: -

Quantity(Bags) 1 – 9 10 – 30 >30 Est. Time(days) 5 7 To be negotiated

Online Customization

Coupling

Features

1. Bushing made of High-strength aluminum alloy

2. The diaphragm is made of 304 stainless steel

3. With high torque capacity, can accurately control shaft rotation, high precision control can be performed

4. For servomotor/stepmotor connect

5. Zero backlash, suitable for high-speed operation

6. Clamp type

Specification

Product picture

Danger

The following misuse may result in life-threatening or serious injury:

1. In order to work safely, coupling and other rotating parts must be protected by the outer cover. If you touch parts of these jobs, you may be hurt.

2. Protective devices must be installed to prevent danger.

3. Power supply must be cut off during installation and disassembly

4. Tightening screw and countersunk head screw shall be tightened with appropriate force by using screwdriver, wrench cargo torsion wrench

5. The working speed of the product should not exceed the maximum speed.

6. Disassembly or reorganization of products is prohibited

Other Products

Spur

Helical

Roller chain

Sprocket

Timing pulley

Linear rail & block